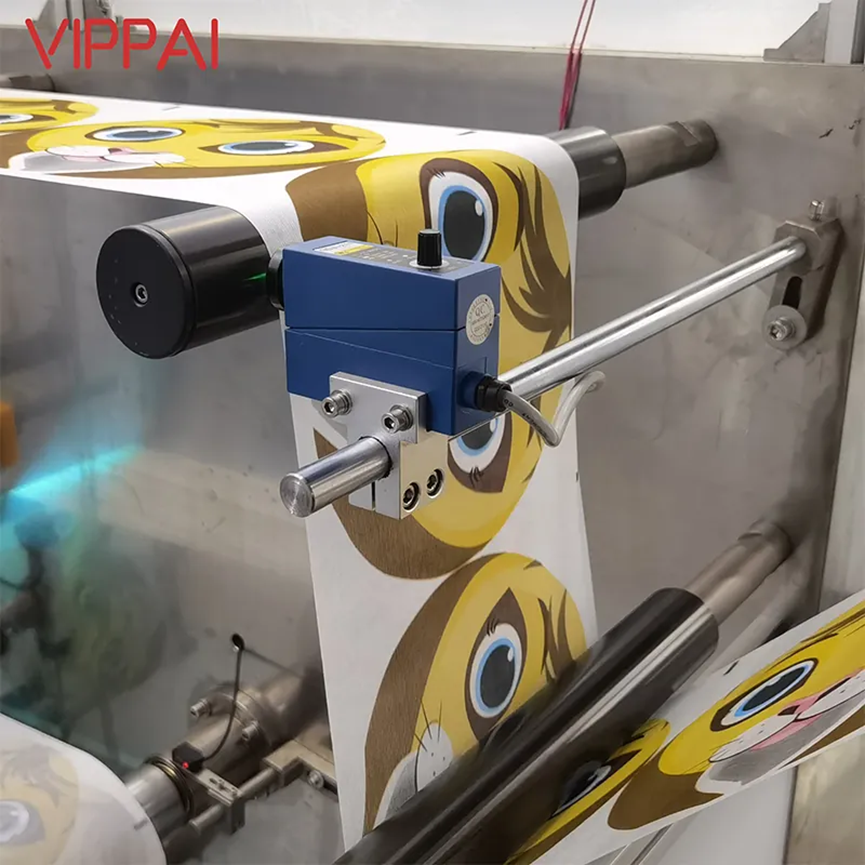

In the realm of cosmetic production, efficiency and precision are paramount. Enter the Vippai VPD-400 Face Sheet Mask Machine, a reliable supplier in the industry. This state-of-the-art automatic filling and sealing machine is improving the way face sheet masks are manufactured, offering a host of benefits for companies worldwide.

Streamlining Production with the VPD-400 Face Sheet Mask Machine

The versatile automatic filling and sealing VPD-400 machine replaces traditional manual workshop equipment such as punching machines, forming machines, folding machines, filling machines, and sealing machines. By doing so, Vippai’s fully automatic packing machine reduces labor requirements by 8-15 workers and minimizes workshop space usage. Notably, the VPD-400 face pack making machine effectively addresses secondary pollution issues during production.

Enhancing Efficiency and Precision

The face sheet mask machine VPD-400 filling process allows for manual inspection with the naked eye, enabling the detection and removal of black spots or other unqualified products through online visual inspection. The face mask sheet making machine uses a high-end metering pump for precise filling, achieving an accuracy of plus or minus 1 gram. This not only ensures quality control but also boosts overall efficiency in the production process.

Conclusion

In conclusion, the Vippai VPD-400 Face Sheet Mask Machine stands as a testament to innovation in the realm of cosmetic production. With features designed to streamline operations, enhance safety, and maintain precision, this machine is a must-have for companies looking to elevate their face sheet mask manufacturing process. Embrace the future of production with the VPD-400 and witness the difference it can make for your business.